In one of our recent social media posts in October, we shared the news about the first Australian laboratory being certified as “green”. The Hill Laboratory at La Trobe University´s Institute of Molecular Science, became the first Aussie lab to receive certification from My Green Lab, a US-based not for profit aimed at improving the sustainability of scientific research.

The article mentions that laboratories use 10 times more energy and four times more water than conventional offices, and many products used for research are single-use only and come densely packed, which obviously result in a large amount of plastic waste.

In order to achieve the certification, La Trobe had applied several measures, including:

- Recycling all soft plastic wrapping, styrofoam, hard plastics and e-waste used in genomic testing;

- Introducing more energy-efficient, heated metal bead baths instead of water baths for keeping samples warm in experiments;

- Changing habits to reduce electricity use, including turning off machines not in use and installing outlet timers;

- Introducing protocols to reduce or eliminate harmful chemicals used in experiments;

- Installing low flow aerators on taps as well as energy-efficient lighting;

- Using a more energy-efficient freezer and cutting back on the number of freezers cooling to -80 degrees Celsius.

When looking at these actions what are your first thoughts that come to mind? Are they realistic goals for every lab?

We definitely celebrate this amazing initiative from The Hill Laboratory to go in this direction, and we can agree that none of these actions seems unachievable for most Australian laboratories.

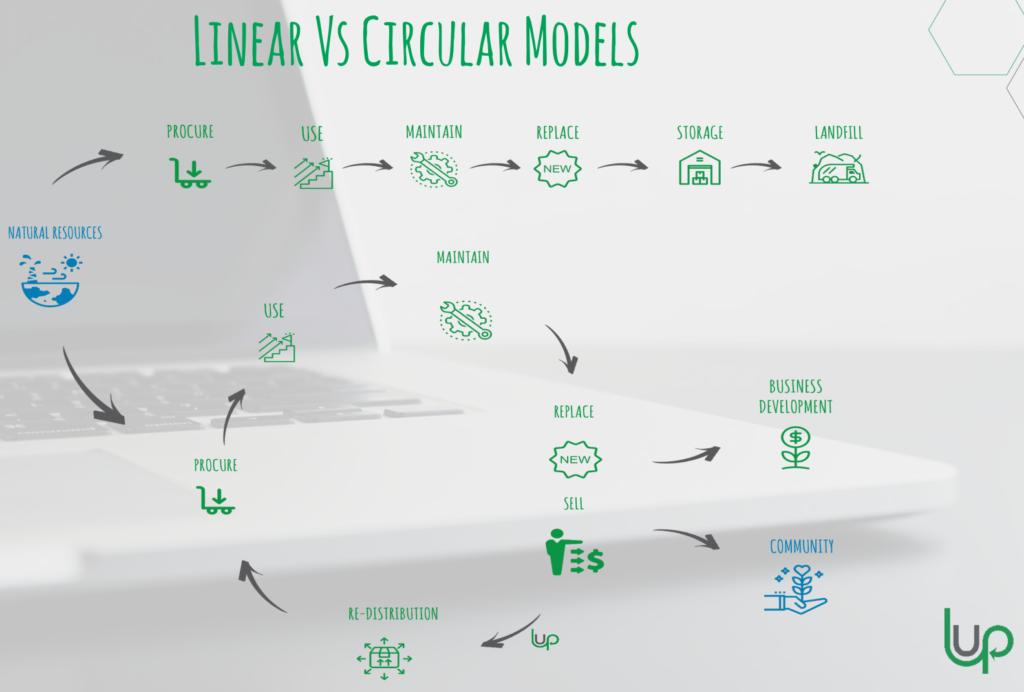

However, the consideration for further improvement, particularly in terms of Capital Equipment and Asset Management could add significantly greater value and is usually under-represented or considered with regards to ‘’waste’’ or sustainability. Since our area of expertise is in Circular Asset Management for laboratories, we understand that labs have massive scope for improvement in this area.

The manufacture of new assets for the industry every year implies tonnes and tonnes of new raw materials, including plastics from fossil fuels, metals, and millions of liters of water and toxins. This system that uses and replaces assets quickly also generates an incredible amount of waste, with us seeing first hand tonnes of laboratory equipment sent to disposal each year even when they are in perfectly usable condition.

This is just not viable anymore, and it is important to consider this aspect of sustainability when doing these certifications or corporate sustainability reports.

At (L)ove (U)r (P)lanet we take a long-term and holistic approach that is an Australian first and doesn’t exist anywhere else in the global market. We ourselves are not a marketplace in that we understand the need to change the approach to life cycle management from the outset in not just being reactive and looking at your assets at the end of the asset life.

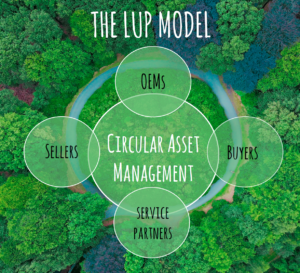

Whilst much grant funding and research in more mainstream Circular Economy modelling focuses on rewarding the re-use, recycling or re-manufacturing of products or assets, at LUP we try to partner with all the stakeholders involved at the initial outset of considering a new Capital Equipment purchase. We partner strategically with all our network members to try to assist them throughout their assets life.

By collaborating with the key stakeholders involved in the life cycles of that asset, including the Original Equipment Manufacturer (OEM), the initial equipment Buyer, to incorporating a network of Service Partners (where the OEM is unable to focus on supporting the equipment in it’s subsequent lives), to finally transitioning the traditional ‘disposal mindset’ of Capital Equipment Buyers to become ‘’Sellers’’ of their equipment at the end of their time with that asset. This way, when the initial Buyer is looking to procure an asset, through LUP they are able to consider the entire life cycle of that asset at the outset, thereby understanding the importance of retaining the maximum value throughout it’s life.

In this way, we enable a sustainable CAPEX process, not only increasing the value of assets on Balance sheets, but reducing risks across company supply chains by ensuring assets are better maintained throughout their life within organisations as well as capturing the optimal residual value once the equipment is no longer required by them.

For second tiered buyers who are able to procure under-utilised equipment, savings in excess of over 60% for good quality laboratory or manufacturing equipment has enabled greater access to resources for start-up laboratories or testing new markets, not to mention keeping valuable equipment out of landfill. We have seen countless instances of laboratories just requiring equipment for one-off purchases, or incorrectly purchased equipment, or not having the test volumes to do the inhouse testing after purchasing and thus continuing to outsource the testing. Thus, not only is partly or fully utilised equipment ending up often in landfill, but equipment that has barely been utilised at all.

So if you are ready to take the leap to the next phase of sustainable evolution, have an even bigger impact on our planet, significantly reduce Procurement costs whilst accessing a viable alternative to the disposal of your under-utilised assets, contact us today to become part of one the fastest growing networks of Circular change makers. Not only can you become more ‘green’ in terms of your operations and operational costs such as The Hill Laboratory has demonstrated, but we will be able to assist you in maximizing your sustainability impact for your capital equipment and the life and value of the assets within your organisation.

Welcome to the (L)ove (U)r (P)lanet family…

Written by Felipe Soraires, edited by Noreen Kam