We are delighted to advise that some big changes are currently happening with LUP Global that will be announced over the coming months…

As a result we will now be moving to a Quarterly newsletter. Our next newsletter will thus be released in October, then the following in January and April.

We are delighted to advise that some big changes are currently happening with LUP Global that will be announced over the coming months…

As a result we will now be moving to a Quarterly newsletter. Our next newsletter will thus be released in October, then the following in January and April.

In the meantime, before the announcement of some big changes in our upcoming October Quarterly newsletter, we would like to bring you the third part of the Guest Expert series with Catherine Weetman.

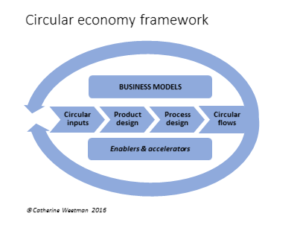

In this month’s update we delve with Catherine more in depth into the elements of her Circular Economy Framework from her book “A Circular Economy Handbook for Business and Supply Chains. Repair, Remake, Redesign, Rethink” which can be purchased online from: A Circular Economy Handbook for Business and Supply Chains.

In the meantime, before the announcement of some big changes in our upcoming October Quarterly newsletter, we would like to bring you the third part of the Guest Expert series with Catherine Weetman.

In this month’s update we delve with Catherine more in depth into the elements of her Circular Economy Framework from her book “A Circular Economy Handbook for Business and Supply Chains. Repair, Remake, Redesign, Rethink” which can be purchased online from: A Circular Economy Handbook for Business and Supply Chains.

Product design aims for a durable, repairable product, able to be disassembled at the end of its final ‘life’ for effective recycling. A robust product could have more ‘use cycles’ and thus be resold by the user, or returned to the producer to be refurbished or remanufactured and then sold again. Companies like Caterpillar and Cummins have dedicated remanufacturing business units that are highly profitable by accessing markets where customers struggle to afford a new product but still want to buy the ‘best in class’ brand. Simplifying the bill of materials to reduce the range and complexity of different materials helps improve the recyclability of the product. Modular designs can improve the speed and ease of repair and upgrades.

Product design aims for a durable, repairable product, able to be disassembled at the end of its final ‘life’ for effective recycling. A robust product could have more ‘use cycles’ and thus be resold by the user, or returned to the producer to be refurbished or remanufactured and then sold again. Companies like Caterpillar and Cummins have dedicated remanufacturing business units that are highly profitable by accessing markets where customers struggle to afford a new product but still want to buy the ‘best in class’ brand. Simplifying the bill of materials to reduce the range and complexity of different materials helps improve the recyclability of the product. Modular designs can improve the speed and ease of repair and upgrades.

Design of the production process should also aim to use less, and close the loop. Can you recover energy and water? Filtering chemicals or biomaterials from the water may provide a by-product to sell, or provide an opportunity for bio-energy. Are there process inputs that can either be re-used, or repurposed? Some major chemical companies are now providing ‘chemicals as a service’, with performance contracts based on the outcomes required and allowing producer and supplier to collaboratively reduce the volume of chemicals required.

Design of the production process should also aim to use less, and close the loop. Can you recover energy and water? Filtering chemicals or biomaterials from the water may provide a by-product to sell, or provide an opportunity for bio-energy. Are there process inputs that can either be re-used, or repurposed? Some major chemical companies are now providing ‘chemicals as a service’, with performance contracts based on the outcomes required and allowing producer and supplier to collaboratively reduce the volume of chemicals required.

Circular flows – how might you recover products, components or materials from your customers, so you can repair, refurbish or remanufacture them to be resold? Are there valuable resources or components that you could reuse, recycle or resell? New businesses are creating value from those recovered materials, perhaps remanufacturing third-party products, reselling products that are durable and repairable, or as a resource recovery and recycling specialist.

Circular flows – how might you recover products, components or materials from your customers, so you can repair, refurbish or remanufacture them to be resold? Are there valuable resources or components that you could reuse, recycle or resell? New businesses are creating value from those recovered materials, perhaps remanufacturing third-party products, reselling products that are durable and repairable, or as a resource recovery and recycling specialist.

Business models aim to provide services and build long-term, win-win relationships, superseding the transactional models typical in the linear economy. A range of approaches include performance contracts, ‘sharing’, short-term rental and longer-term leases (perhaps with maintenance included), and subscriptions.

Enablers and accelerators can help to close the loop. Enablers include new knowledge and different ways of thinking, such as green chemistry, industrial ecology, biomimicry and systems thinking. Accelerators help scale-up the transformation, and include Product Stewardship legislation, Eco-design standards, taxes and incentives to encourage businesses and their customers to close the loop.

Business models aim to provide services and build long-term, win-win relationships, superseding the transactional models typical in the linear economy. A range of approaches include performance contracts, ‘sharing’, short-term rental and longer-term leases (perhaps with maintenance included), and subscriptions.

Enablers and accelerators can help to close the loop. Enablers include new knowledge and different ways of thinking, such as green chemistry, industrial ecology, biomimicry and systems thinking. Accelerators help scale-up the transformation, and include Product Stewardship legislation, Eco-design standards, taxes and incentives to encourage businesses and their customers to close the loop.

In the meantime, before the announcement of some big changes in our upcoming October Quarterly newsletter, we would like to bring you the third part of the Guest Expert series with Catherine Weetman.

In this month’s update we delve with Catherine more in depth into the elements of her Circular Economy Framework from her book “A Circular Economy Handbook for Business and Supply Chains. Repair, Remake, Redesign, Rethink” which can be purchased online from: A Circular Economy Handbook for Business and Supply Chains.

In the meantime, before the announcement of some big changes in our upcoming October Quarterly newsletter, we would like to bring you the third part of the Guest Expert series with Catherine Weetman.

In this month’s update we delve with Catherine more in depth into the elements of her Circular Economy Framework from her book “A Circular Economy Handbook for Business and Supply Chains. Repair, Remake, Redesign, Rethink” which can be purchased online from: A Circular Economy Handbook for Business and Supply Chains.

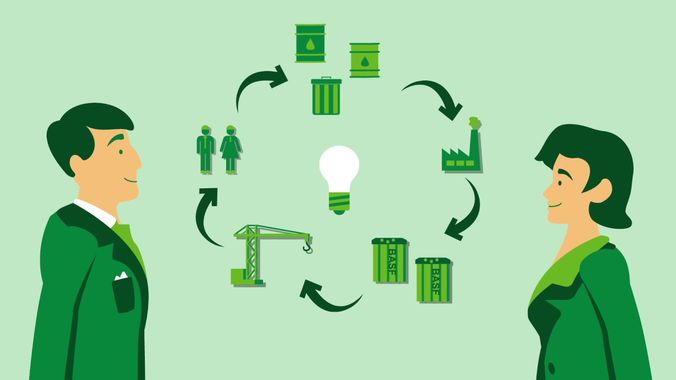

Part 3 : Feature Guest Expert Catherine Weetman (UK) summarises circular economy approaches

Following last month’s introduction to Circular Economies (CE), in this month’s update, we look briefly at the approaches you might take for each of the elements in Catherine’s CE framework: Circular inputs (materials) should be from sustainable sources: either recycled instead of virgin materials; or renewable within the lifetime of the product. For example, if you make a wooden table and it takes 15 years to grow the tree, the table should have a design life of more than 15 years. The aim is security of supply, and resources that are safe for humans and living systems, throughout the cycle from material sourcing, through production and use to end-of-use. Product design aims for a durable, repairable product, able to be disassembled at the end of its final ‘life’ for effective recycling. A robust product could have more ‘use cycles’ and thus be resold by the user, or returned to the producer to be refurbished or remanufactured and then sold again. Companies like Caterpillar and Cummins have dedicated remanufacturing business units that are highly profitable by accessing markets where customers struggle to afford a new product but still want to buy the ‘best in class’ brand. Simplifying the bill of materials to reduce the range and complexity of different materials helps improve the recyclability of the product. Modular designs can improve the speed and ease of repair and upgrades.

Product design aims for a durable, repairable product, able to be disassembled at the end of its final ‘life’ for effective recycling. A robust product could have more ‘use cycles’ and thus be resold by the user, or returned to the producer to be refurbished or remanufactured and then sold again. Companies like Caterpillar and Cummins have dedicated remanufacturing business units that are highly profitable by accessing markets where customers struggle to afford a new product but still want to buy the ‘best in class’ brand. Simplifying the bill of materials to reduce the range and complexity of different materials helps improve the recyclability of the product. Modular designs can improve the speed and ease of repair and upgrades.

Design of the production process should also aim to use less, and close the loop. Can you recover energy and water? Filtering chemicals or biomaterials from the water may provide a by-product to sell, or provide an opportunity for bio-energy. Are there process inputs that can either be re-used, or repurposed? Some major chemical companies are now providing ‘chemicals as a service’, with performance contracts based on the outcomes required and allowing producer and supplier to collaboratively reduce the volume of chemicals required.

Design of the production process should also aim to use less, and close the loop. Can you recover energy and water? Filtering chemicals or biomaterials from the water may provide a by-product to sell, or provide an opportunity for bio-energy. Are there process inputs that can either be re-used, or repurposed? Some major chemical companies are now providing ‘chemicals as a service’, with performance contracts based on the outcomes required and allowing producer and supplier to collaboratively reduce the volume of chemicals required.

Circular flows – how might you recover products, components or materials from your customers, so you can repair, refurbish or remanufacture them to be resold? Are there valuable resources or components that you could reuse, recycle or resell? New businesses are creating value from those recovered materials, perhaps remanufacturing third-party products, reselling products that are durable and repairable, or as a resource recovery and recycling specialist.

Circular flows – how might you recover products, components or materials from your customers, so you can repair, refurbish or remanufacture them to be resold? Are there valuable resources or components that you could reuse, recycle or resell? New businesses are creating value from those recovered materials, perhaps remanufacturing third-party products, reselling products that are durable and repairable, or as a resource recovery and recycling specialist.

Business models aim to provide services and build long-term, win-win relationships, superseding the transactional models typical in the linear economy. A range of approaches include performance contracts, ‘sharing’, short-term rental and longer-term leases (perhaps with maintenance included), and subscriptions.

Enablers and accelerators can help to close the loop. Enablers include new knowledge and different ways of thinking, such as green chemistry, industrial ecology, biomimicry and systems thinking. Accelerators help scale-up the transformation, and include Product Stewardship legislation, Eco-design standards, taxes and incentives to encourage businesses and their customers to close the loop.

Business models aim to provide services and build long-term, win-win relationships, superseding the transactional models typical in the linear economy. A range of approaches include performance contracts, ‘sharing’, short-term rental and longer-term leases (perhaps with maintenance included), and subscriptions.

Enablers and accelerators can help to close the loop. Enablers include new knowledge and different ways of thinking, such as green chemistry, industrial ecology, biomimicry and systems thinking. Accelerators help scale-up the transformation, and include Product Stewardship legislation, Eco-design standards, taxes and incentives to encourage businesses and their customers to close the loop.

News Corner

One Less Thing: Living Without Trash | Manuela Baron A great Ted talk for inspiring us all as consumers to living with less trash