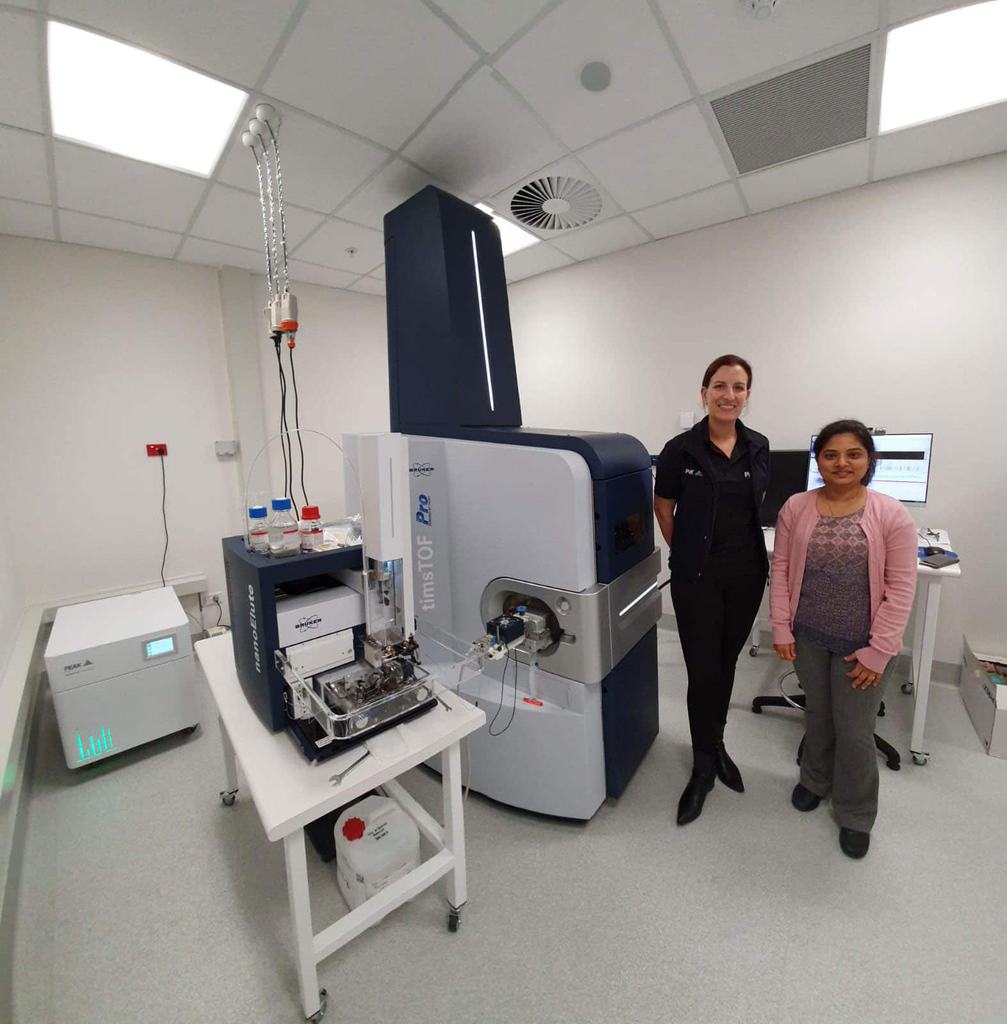

Guest Expert Interview – Irena Jovanovska, Founder of Swinburne University’s Women in STEM Club

Last year we were delighted to welcome Irena Jovanovska to the LUP family. With an impressive background, Irena founded the Women in STEM club at Swinburne University where she completed her Master’s in Science (Biotechnology) degree. Later this year we are planning on holding our first live event with Swinburne University and their Women in STEM Club. We thought we would thus take this opportunity to discuss with Irena her reasons for why she set up this club with now 150 members and growing. We wanted to highlight the amazing work they were set up to do and continue to do now and in the future…”

LUP: Thanks for taking the time to sit down with us Irena. So back in 2019, you founded the Women in STEM club at Swinburne. Can you please give us an insight into why you set up the club & why you felt the need for the club was at that time?

Irena: It is my pleasure, thank you for having me! It all began when I attended the Australian Symposium for Women leaders in August 2018. Finding myself amongst women leaders was very motivational and inspired me to think of myself as a leader as well. Whereas before that I never even considered the possibility that I could also become an inspiration for others. I thought that my success thus far was only ‘luck’ and ‘accidents’ that happened along the way, but I realised that it was actually the result of hard work and perseverance.

I then got included in the gender equity group at Swinburne, and subsequently the Women in STEM Faculty Group lead by Dr Tania Moein. Having that insight, and being the voice for women in STEM as a student representative, I noticed the things that could be developed further and new ideas to be implemented that would improve the experience of women and other minority groups in the STEM fields during the studies, as well as in a working environment. The crux of it was starting a club for supporting and empowering women in STEM.

LUP: What sort of work were you looking at doing or having the club focus on?

Irena: The initial purpose of the club was to have a place where we can support one another, celebrate our success, and share our concerns. Also, considering that the women are proportionally less represented in the STEM fields for a number of reasons, the club is a ‘safe space’ where we can all brainstorm and improve our personal and professional wellbeing and gain the courage to raise our hands and speak up.

Generally speaking, the Women in STEM Club aims to create an empowering, inclusive, and supportive environment at Swinburne. I must highlight the amazing support we experienced from our teaching staff as well as from other already established clubs. We dedicated the first semester to set up strong foundations upon which the success kept piling on. So far we’ve held many social and professional events and shared opportunities: trivia, networking, discussions, game nights, STEM and industry webinars, professional networking, competitions, etc.

LUP: Has it changed much since & have you got any messages to deliver to the next generation of leading female scientists?

IRENA: Oh, it most definitely changed! It evolved to celebrate diversity, and consistently engage the club members in various ways. I am especially proud of the collaborations with other clubs, organisations and professionals in STEM at Swinburne and some industry collaborations which provide an array of opportunities for our students and can sometimes lead to fruitful career progressions! We also developed the Women in STEM mentor program and the Women can STEM program and held mental health events full of ideas on how to get through the pandemic lockdowns.

My message to future generations is to lead by example, help and guide others, be compassionate and understanding. But, most importantly, take care of yourself first, believe in yourself and give yourself credit for all your success. If no one has accomplished what you aim to achieve, it doesn’t mean it is impossible. It only means that you could be the first one to do it! Take it as a challenge!

LUP: How can you see LUP continue to be able to best support the Women in STEM club at Swinburne & how else can people & organisations within the LUP network help? eg. mentoring programs etc

IRENA: LUP Global can support the Women in STEM club members by sharing their personal achievement journey, holding regular networking events, and workshops. Furthermore, starting personal development programs, providing internships and other collaborations would be very beneficial for our club members’ careers. LUP Global can also be included in a mentorship program where the club members can get personalised advice about their career directly from the successful leaders in LUP Global.