Circular Asset Management for Laboratories, Why Under-Utilised Equipment Makes Sense

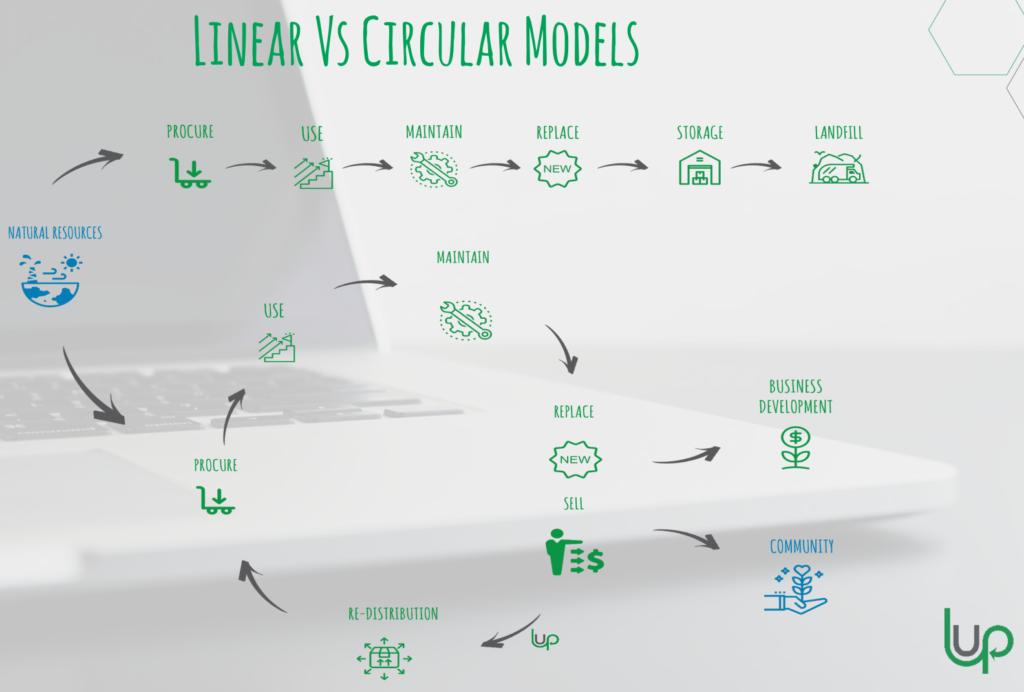

At (L)ove (U)r (P)lanet we are convinced that businesses can be both profitable and successful through focusing on the betterment of society and our planet as a whole. This is why we adopt Circular Asset Management practices and work with organisations who can mutually benefit from prolonging the lifecycles of their assets -specifically for laboratory and manufacturing equipment-, through the optimisation and re-allocation of these assets.

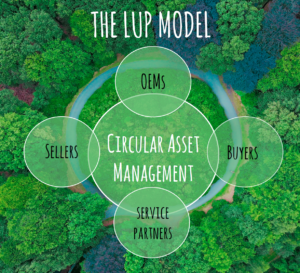

Our holistic network brings together all stakeholders: Original Equipment Manufacturers (OEM’s), Laboratories and Manufacturers (Buyers/Sellers) and Service Partners, with whom we work on a case-by-case basis considering the entirety of Asset Life Cycles, with the ultimate aim of reducing landfill and mining more raw materials from the planet.

But our business model brings benefits not only for the environment. The economic benefits are essential for us, and in this whitepaper –inspired by Matt Hicks, Chief Operating Officer at Federal Equipment Company, a pharmaceutical industry veteran with more than 15 years of experience helping companies get the most value and utility out of their manufacturing and process equipment assets. In Hicks article published by Pharmasalmanac – he explores in detail, why choosing under-utilised equipment can become a competitive advantage for your company.

There are many situations in which companies could receive more benefits opting for purchasing under-utilised equipment rather than new, and the main reason behind is that you will be able to save time and money, making your company more competitive in the market.

In a very dynamic and fast-changing environment which often businesses are, market conditions may require rapid increases in capacity, offering great opportunities for flexible organisations which can adapt their operations to the demand. According to Hicks, sourcing new equipment can at times require a 6-8 month lead time for delivery. This has been further exacerbated since COVID.

Meanwhile second-hand equipment can be purchased faster, particularly within the Australian market where most of the manufacturing occurs offshore, allowing companies to operate on shorter turn-arounds & schedules. As a complementary benefit, this equipment is usually significantly cheaper than new, which makes them a particularly attractive alternative for research institutes with limited funding, plus smaller or start-up laboratories with reduced R&D budgets. At (L)ove (U)r (P)lanet, we have seen instances of equipment comparative to new at a fraction of the cost, saving savvy Circular Asset Buyers in excess of 60% off new. And yet, when we often say our focus is to try to minimise landfill, many people automatically assume under-utilised equipment is at the end of life. Yet this is far from the case. In our first two years of Operation, approximately 60% of our asset base was under 3 years old.

Another great benefit of acquiring used equipment is in terms of quality improvement and process consistency in a faster way with lower capital expenditure. Used equipment can mitigate considerably all the risks related with the supply chain, ensuring on-time delivery for your projects. The difficulties that the pandemic brought to global supply chains are visible across most industry sectors, and the effects seem to stay for longer. Diversifying your supply chain with the Procurement of Circular Assets will help you reduce uncertainty and avoid sudden stops within your operations.

Purchasing new equipment can also demand more caution compared to used ones, including: qualifying and selecting new supplier/s, customizing the new equipment to the process, testing the machinery at the OEM´s facilities and then in the laboratory. All these processes are more complex when the equipment is new, without considering any complications with the physical delivery of the unit, which (unfortunately) occurs quite frequently.

For under-utilised equipment, it is still key to find a reputable supplier with experience in the market. The main difference is in time and cost: as the equipment is already built, the process can potentially reduce purchase lead time from months to weeks and the cost savings are substantial. There are many reasons for choosing Circular Assets, including market opportunities, operative reasons, but maybe more importantly, it could be a great way to become more competitive with a time/money-saving solution whilst contributing to longer term sustainable outcomes.

At (L)ove (U)r (P)lanet we have the experience to help you to find the right solutions for your capital equipment and sustainable procurement needs, always seeking a WIN-WIN-WIN outcome and the best interest for Your Company, our Circular Network and of course, Our Planet!

Written by Felipe Soraires, edited by Noreen Kam